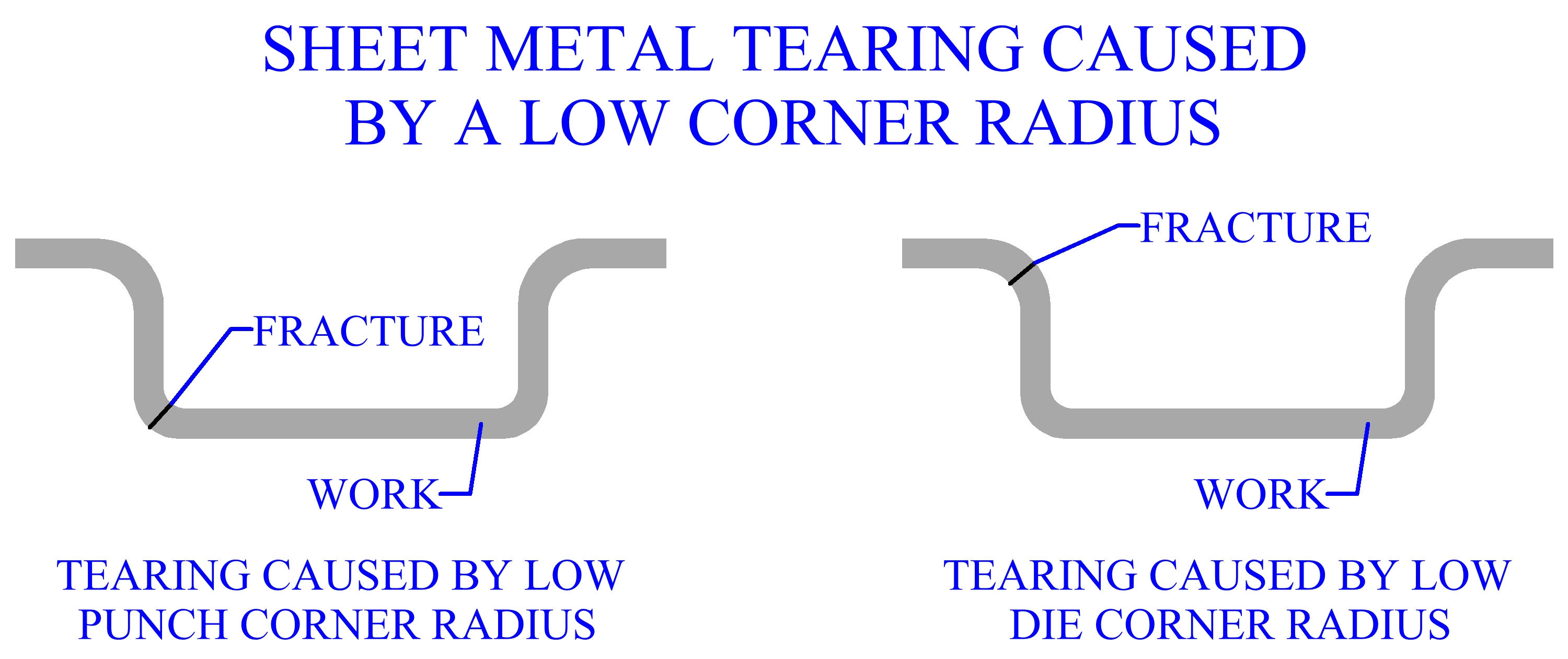

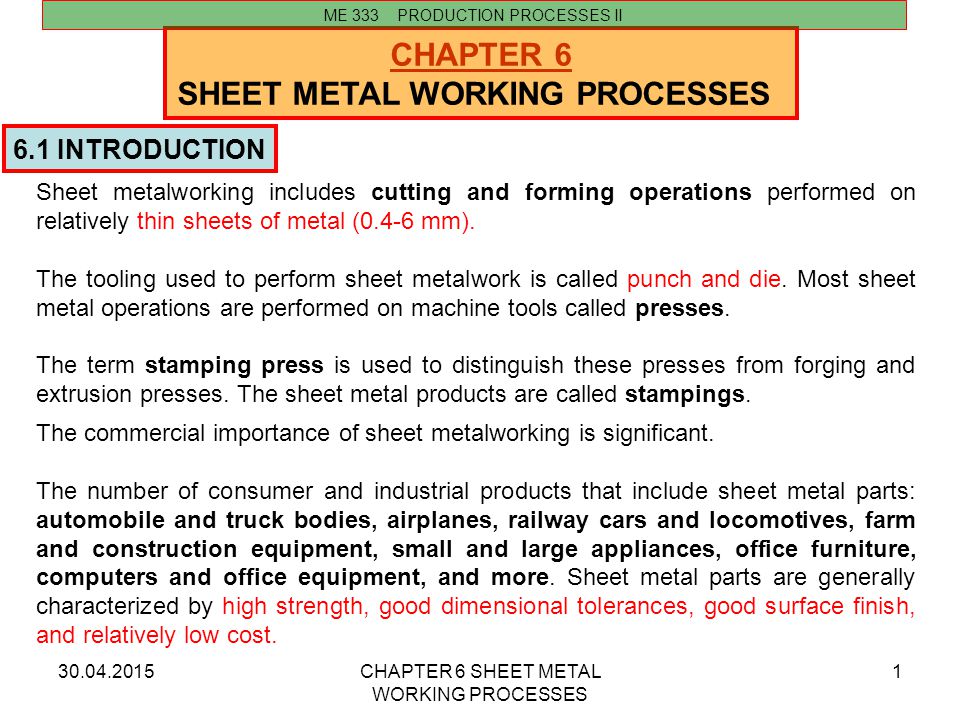

A large factor is the type of work material and its temper.

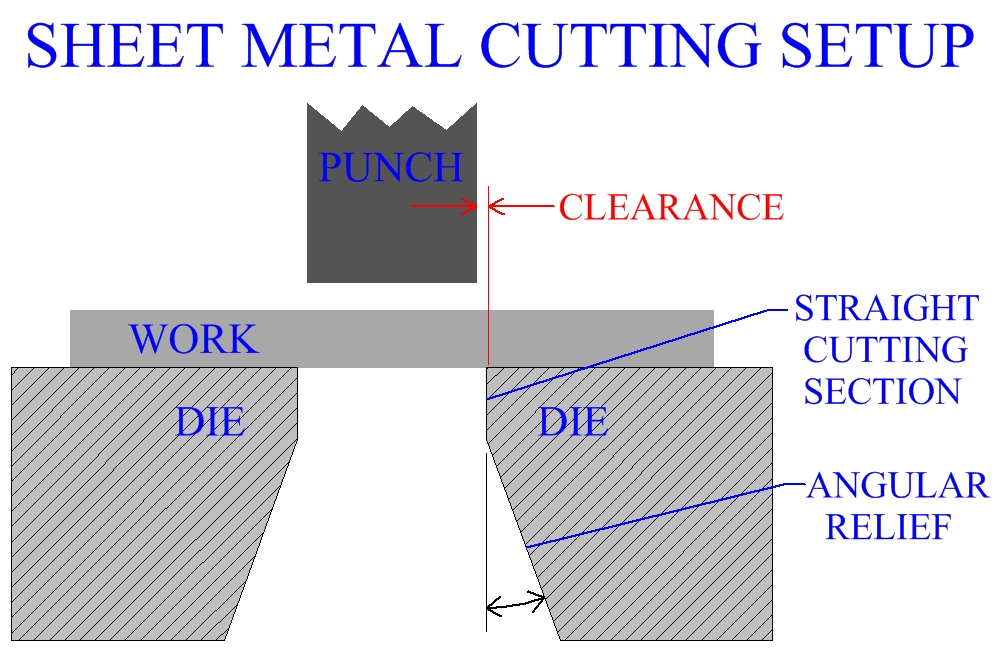

As sheet metal stock thickness increases the clearance between punch and die should.

A long time industry rule of thumb used by die makers for the clearance between the punch and the die button is 5 of the stock thickness per side.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

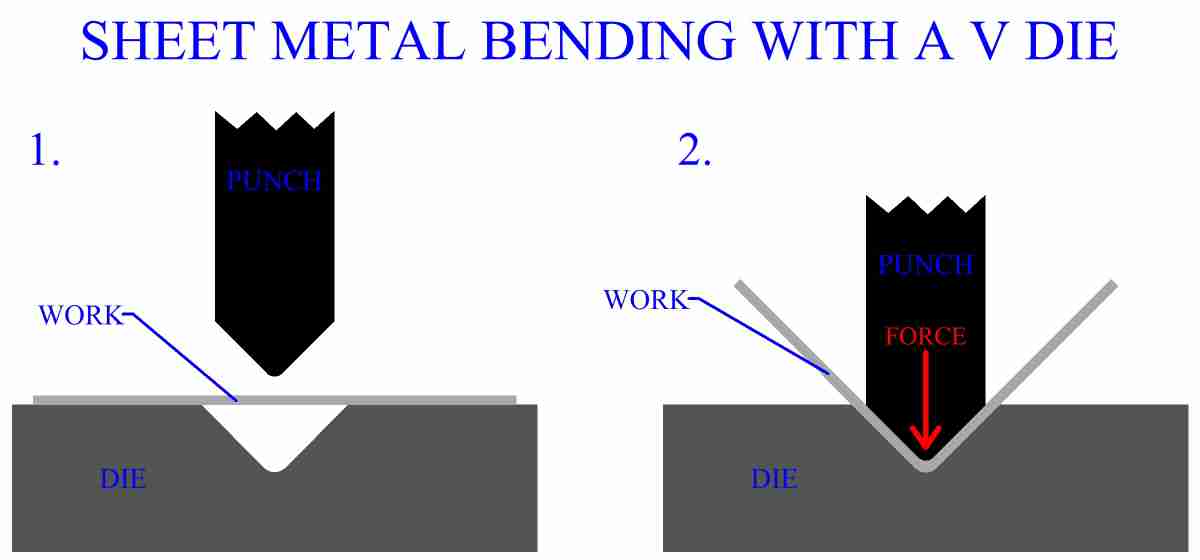

This depth is precisely controlled to achieve the required bend.

Min service life of dies.

30 heavy duty die clearance.

The greater the sheet metal thickness the higher the clearance value should be.

Generally typical values span from 3 to 8 of sheet thickness.

A be decreased b be increased or c be unaffected.

If you have too much clearance the material will stretch before the material fractures to produce the slug.

30 table 1 recommended die clearance table.

A circular sheet metal slug produced in a hole punching operation will have the same diameter as a the die opening or b the punch.

As sheet metal stock hardness increases the clearance between punch and die should.

16 6 as sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

This adds stress to the sheet and increases distortion.

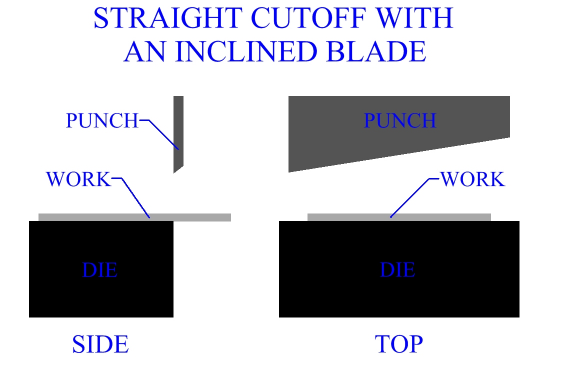

The sheet is placed between the two and held in place by the backstop.

The press brake contains an upper tool called the punch and lower tool called the die between which the sheet metal is placed.

The percentage of the die clearance to the material thickness.

B be increased a round sheet metal slug produced in a hole punching operation will have the same diameter as.

In manufacturing industry there is a range of optimum values for specific processes clearances may span from 1 to 30 of sheet thickness.

Determine the punch and die clearance by experience.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

Next make sure you have the correct die clearance for the material type and thickness you re punching see figure 2.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be increased a circular sheet metal slug produced in a hole punching operation will have the same diameter as the.

This provided an acceptable burr height and slug control.

Increased 16 7 a circular sheet metal slug produced in a hole punching operation will have the same diameter as the a die opening or b punch.